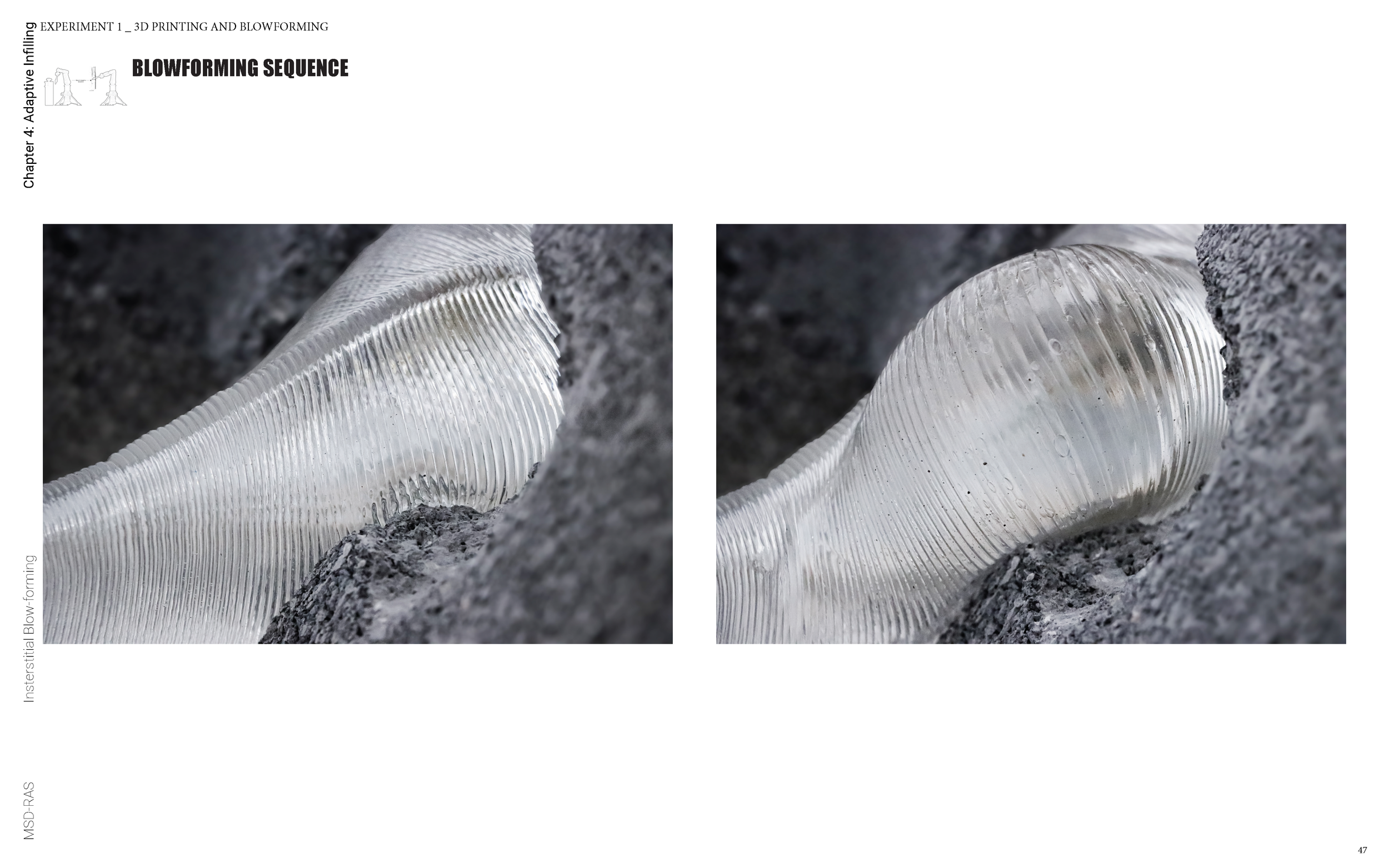

Interstitial Blow-forming:

Real-time crack detection and robotic blow-forming for spatial reactivation.

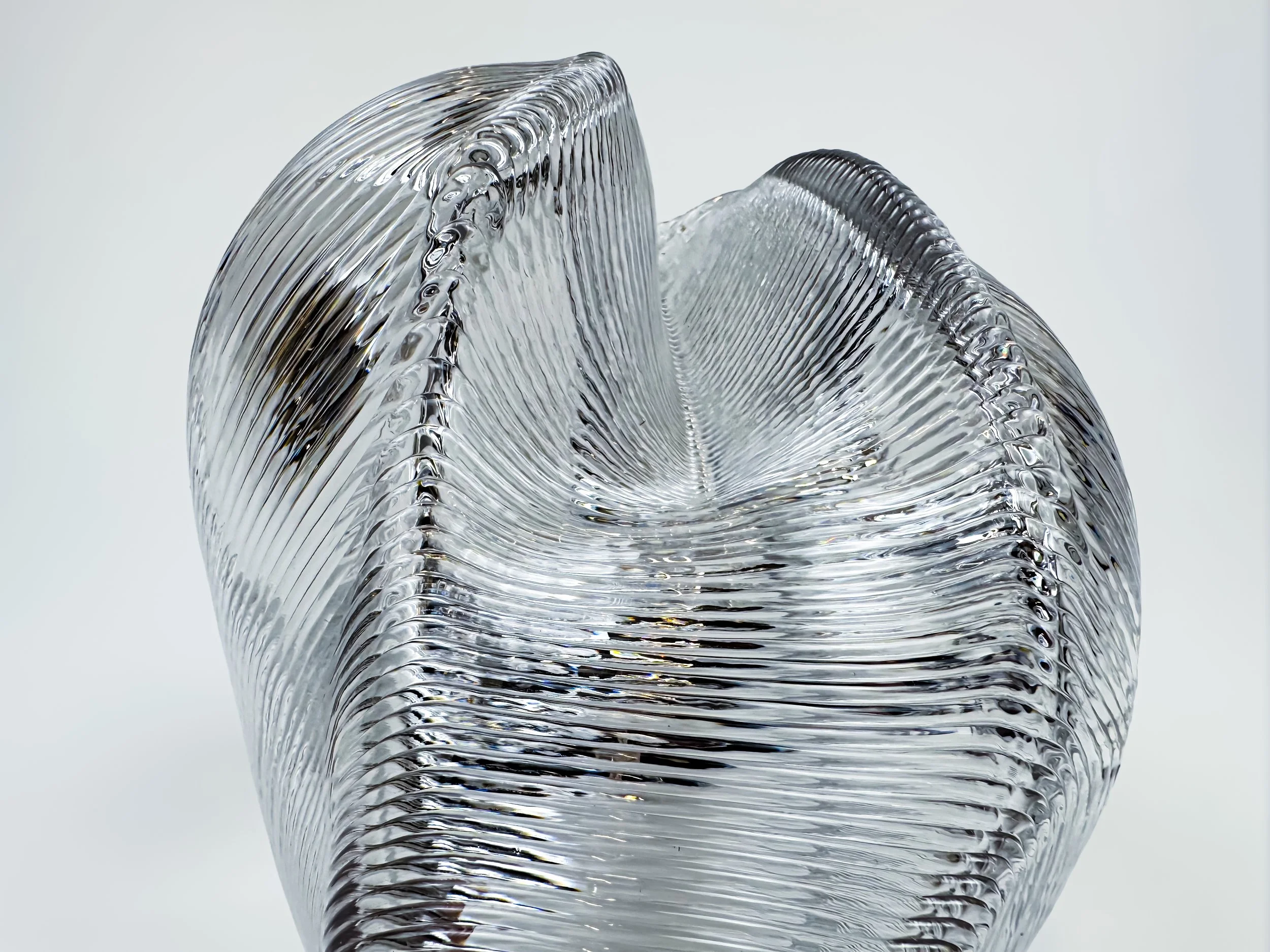

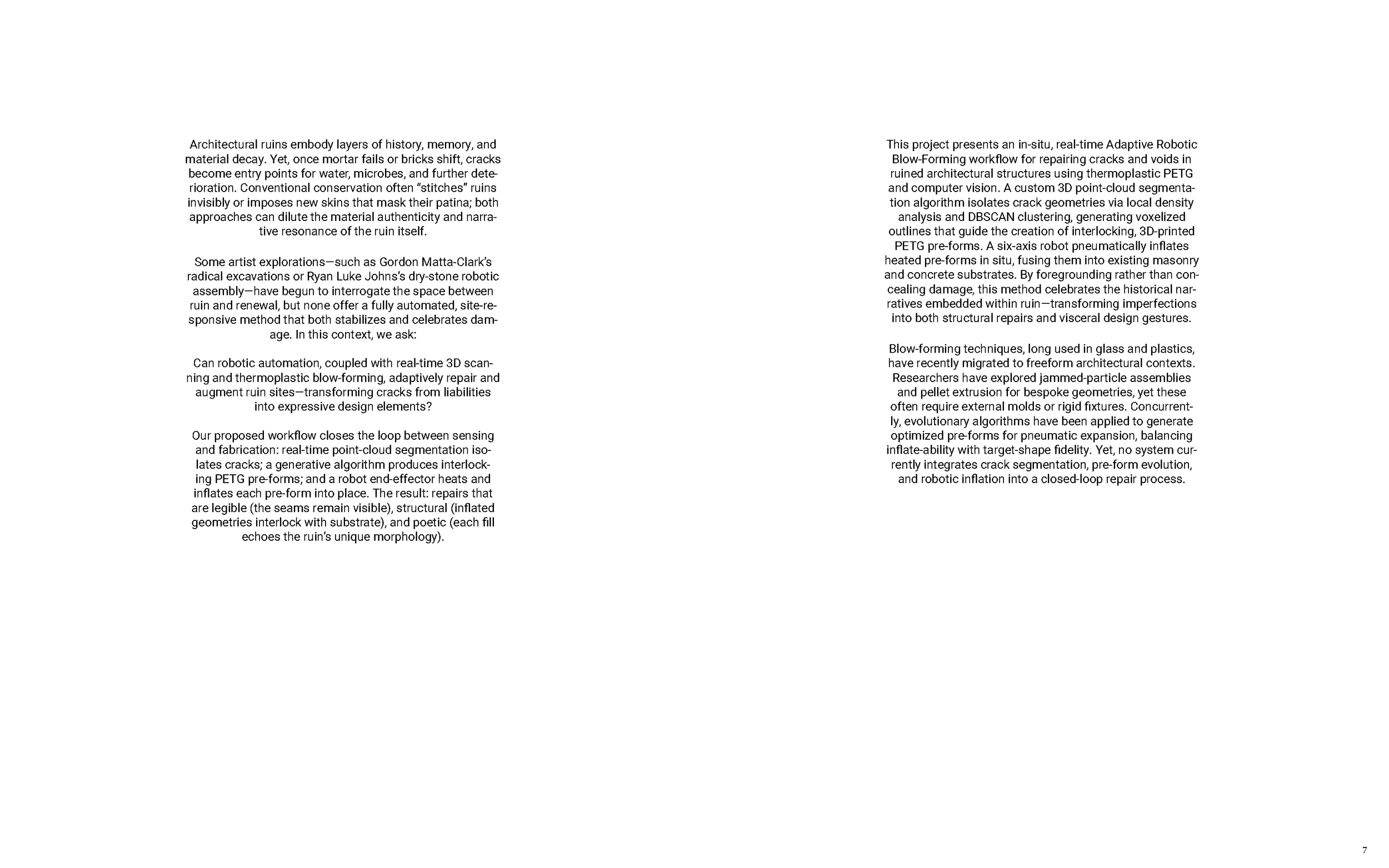

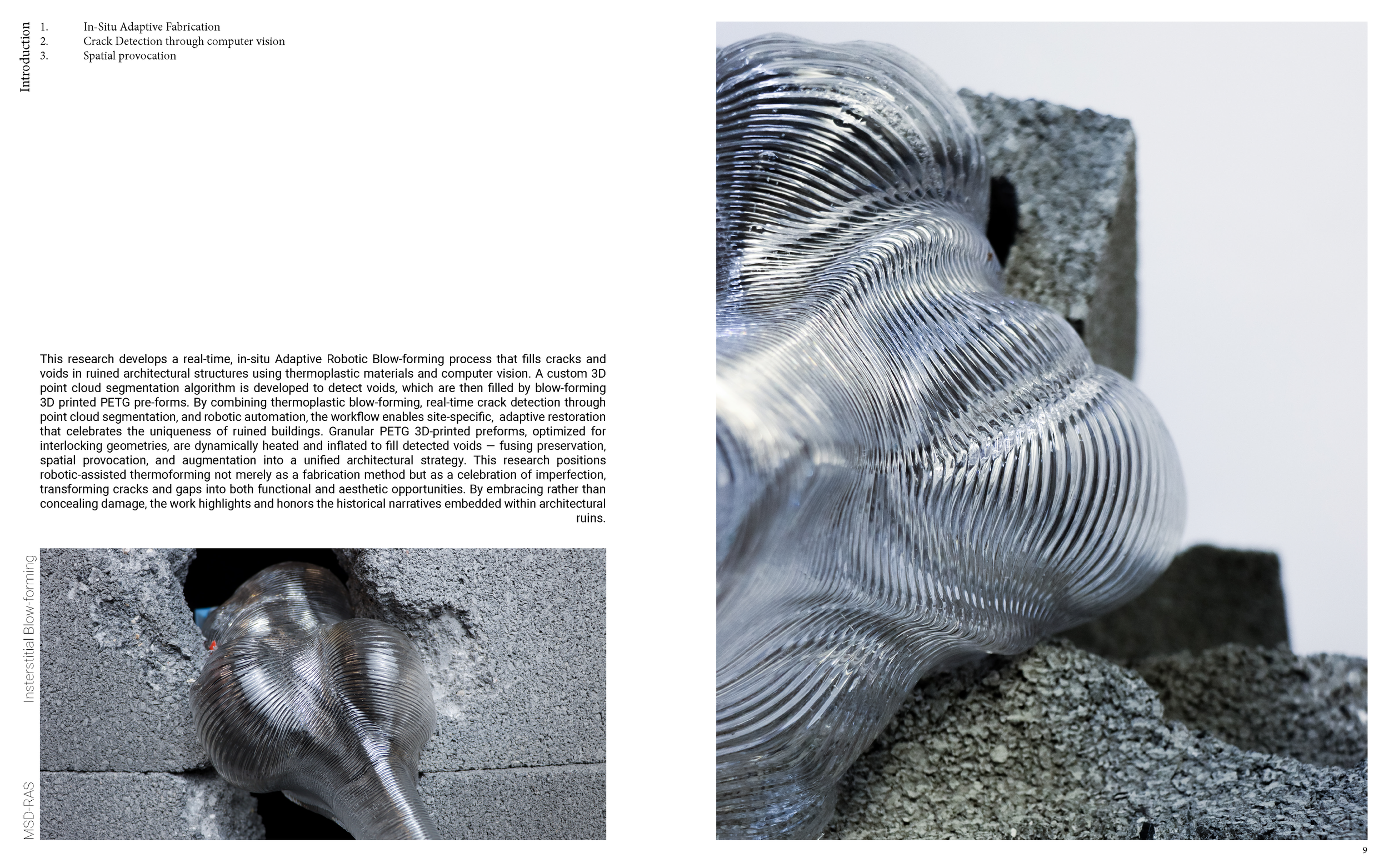

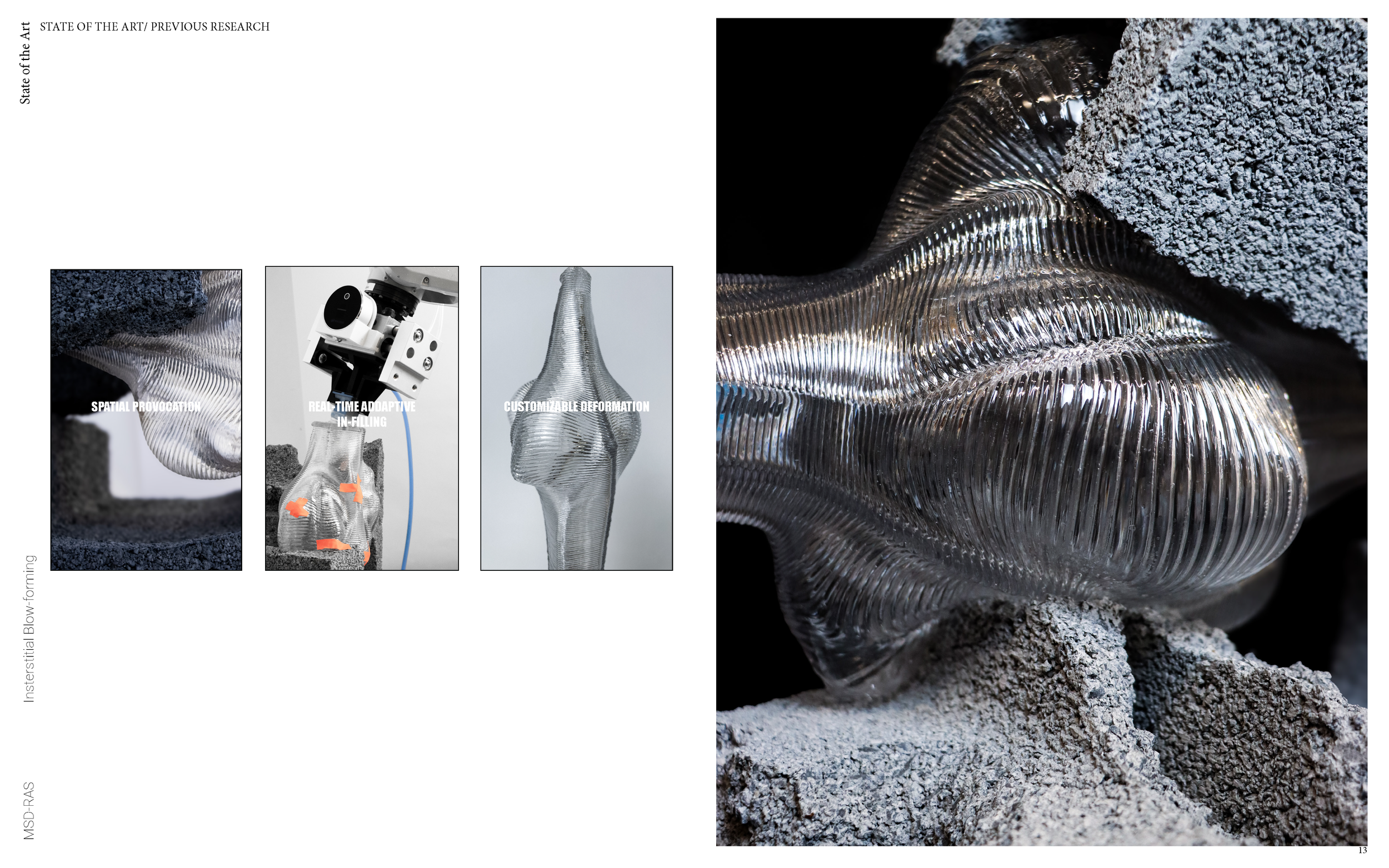

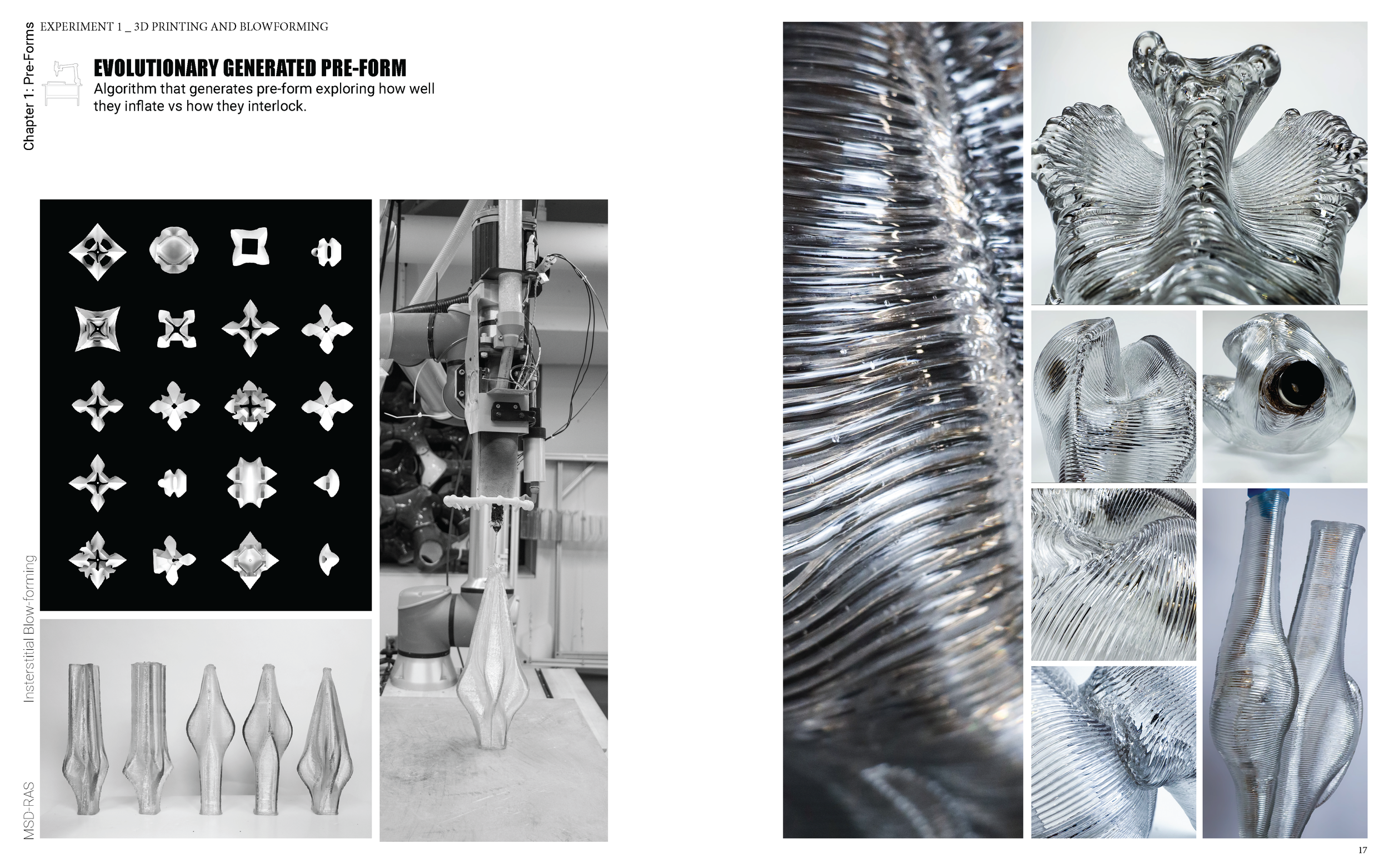

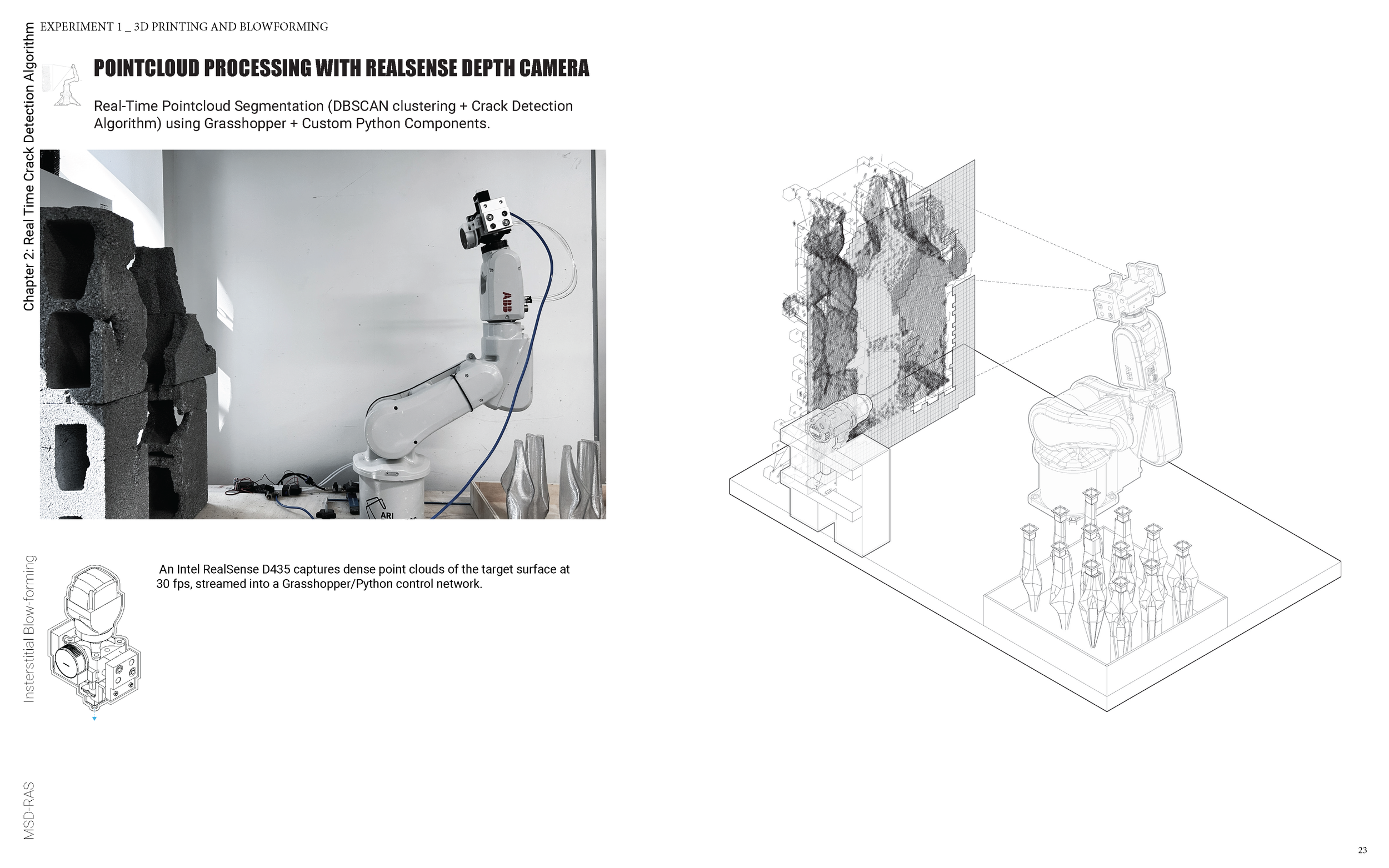

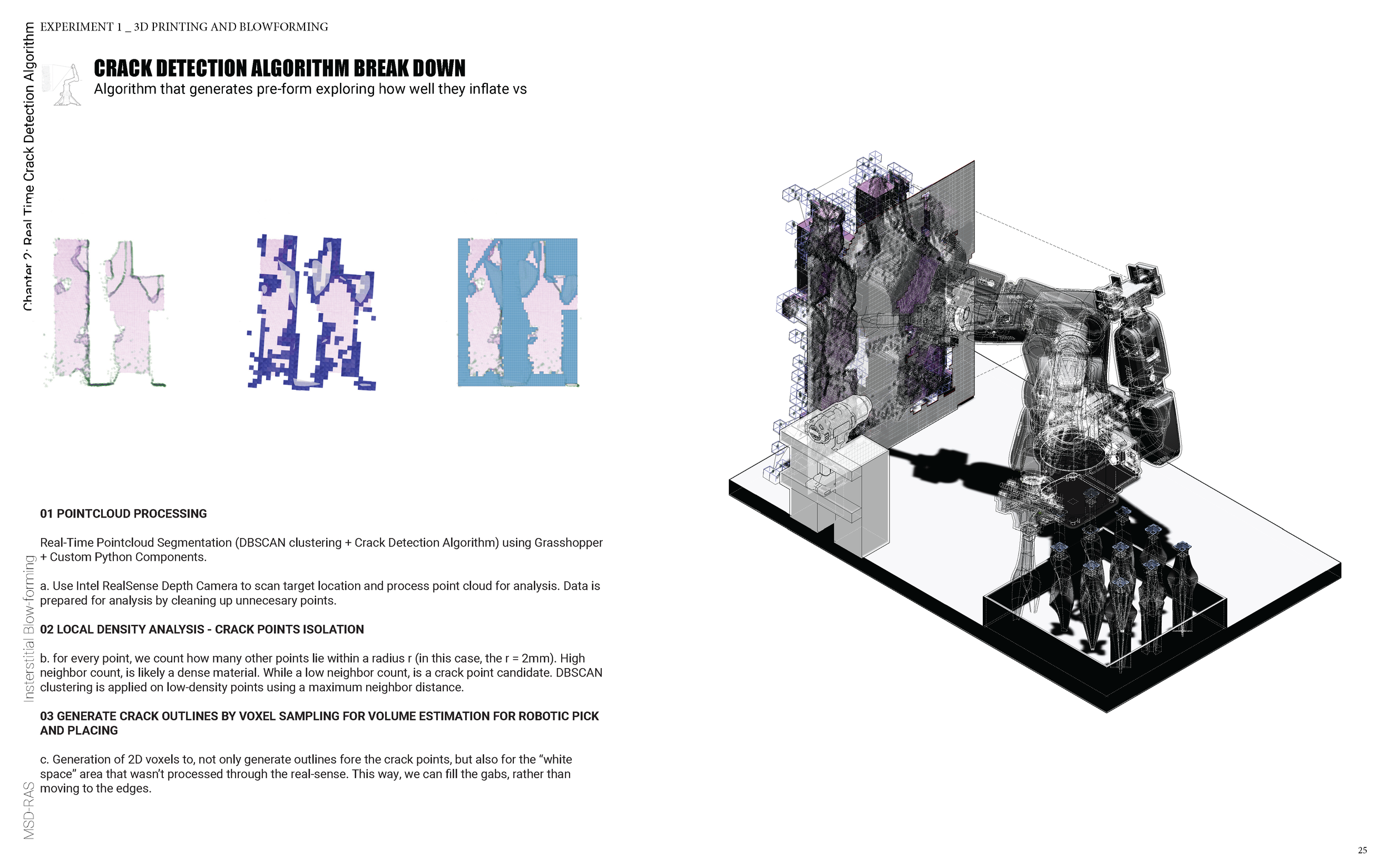

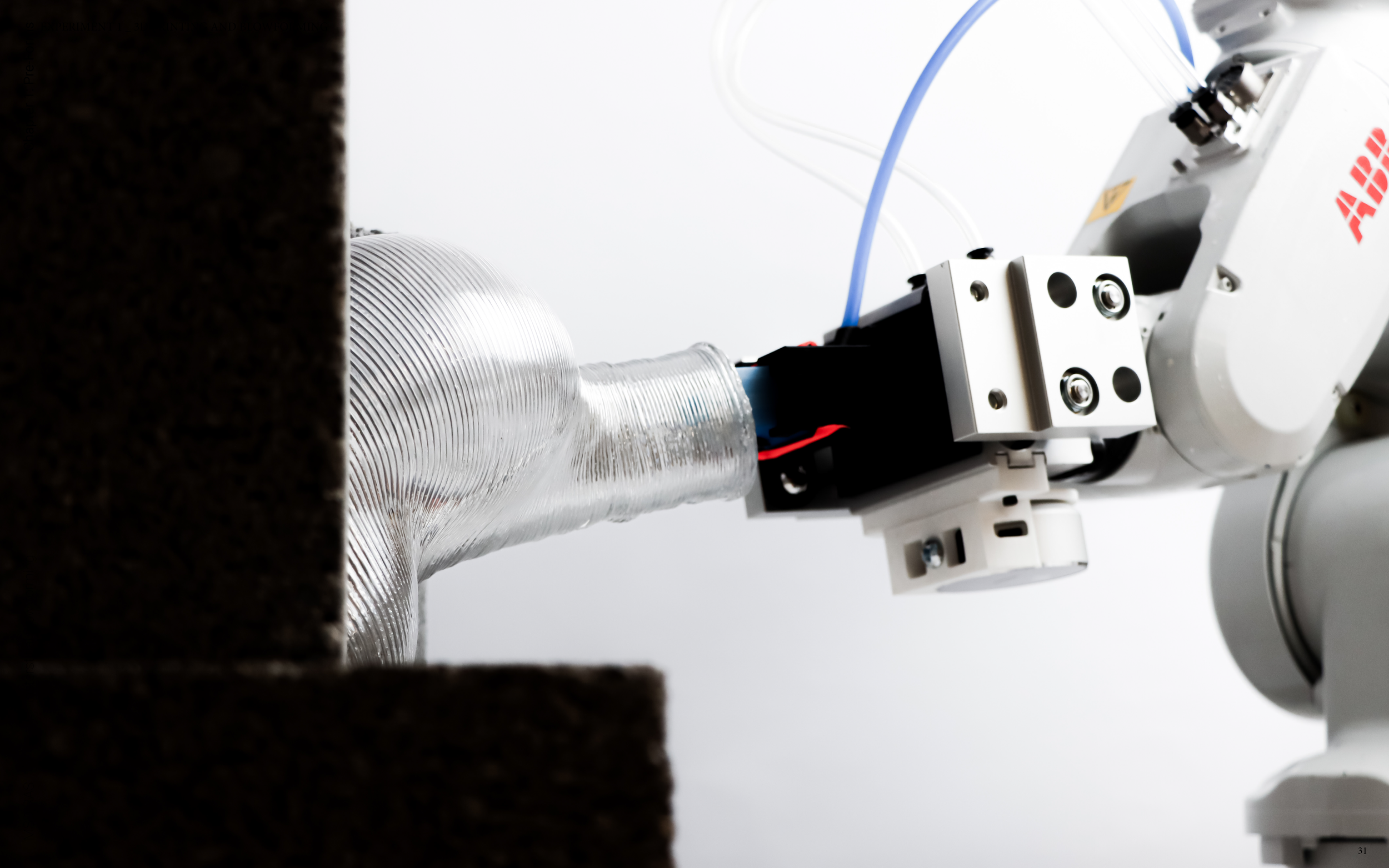

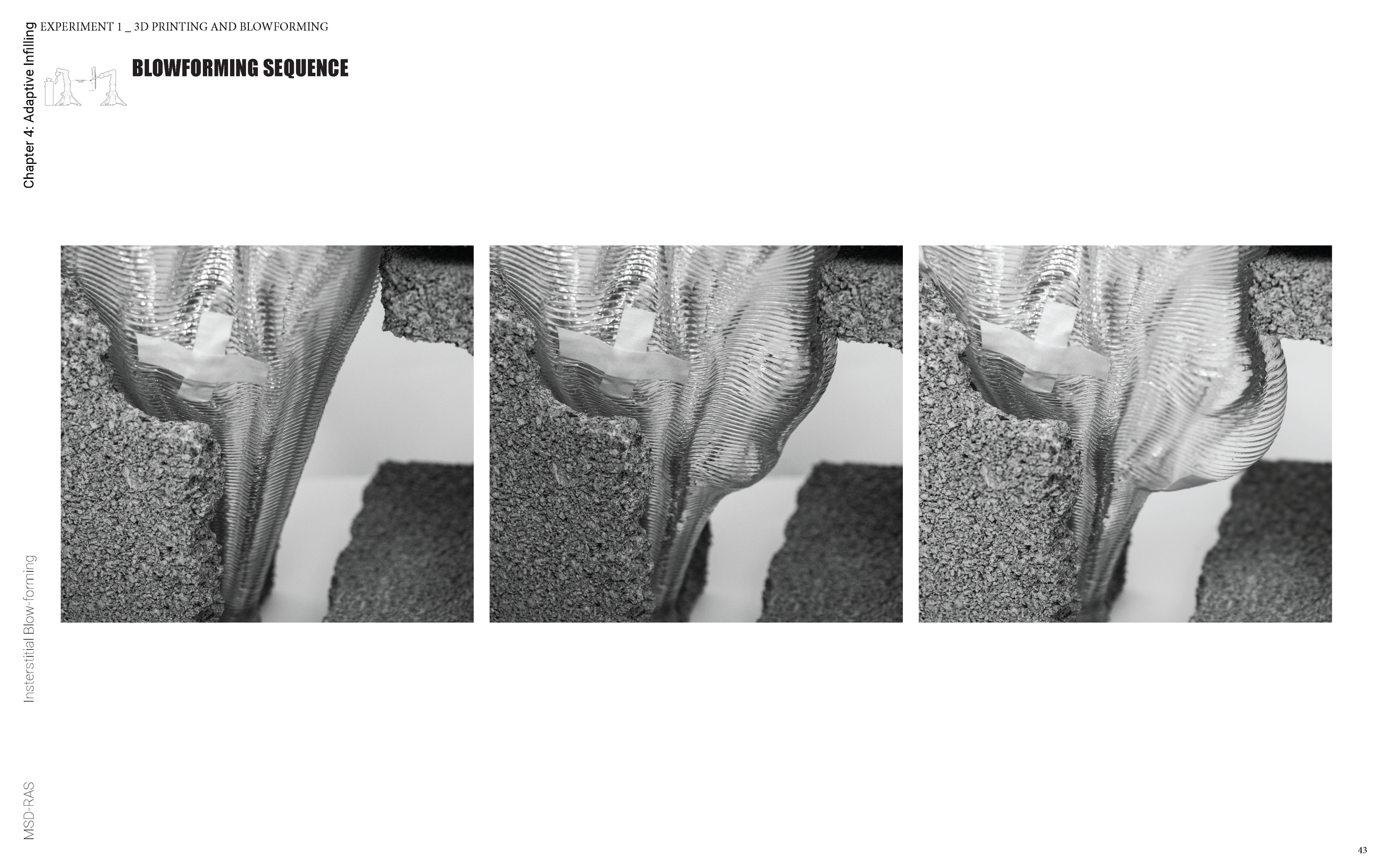

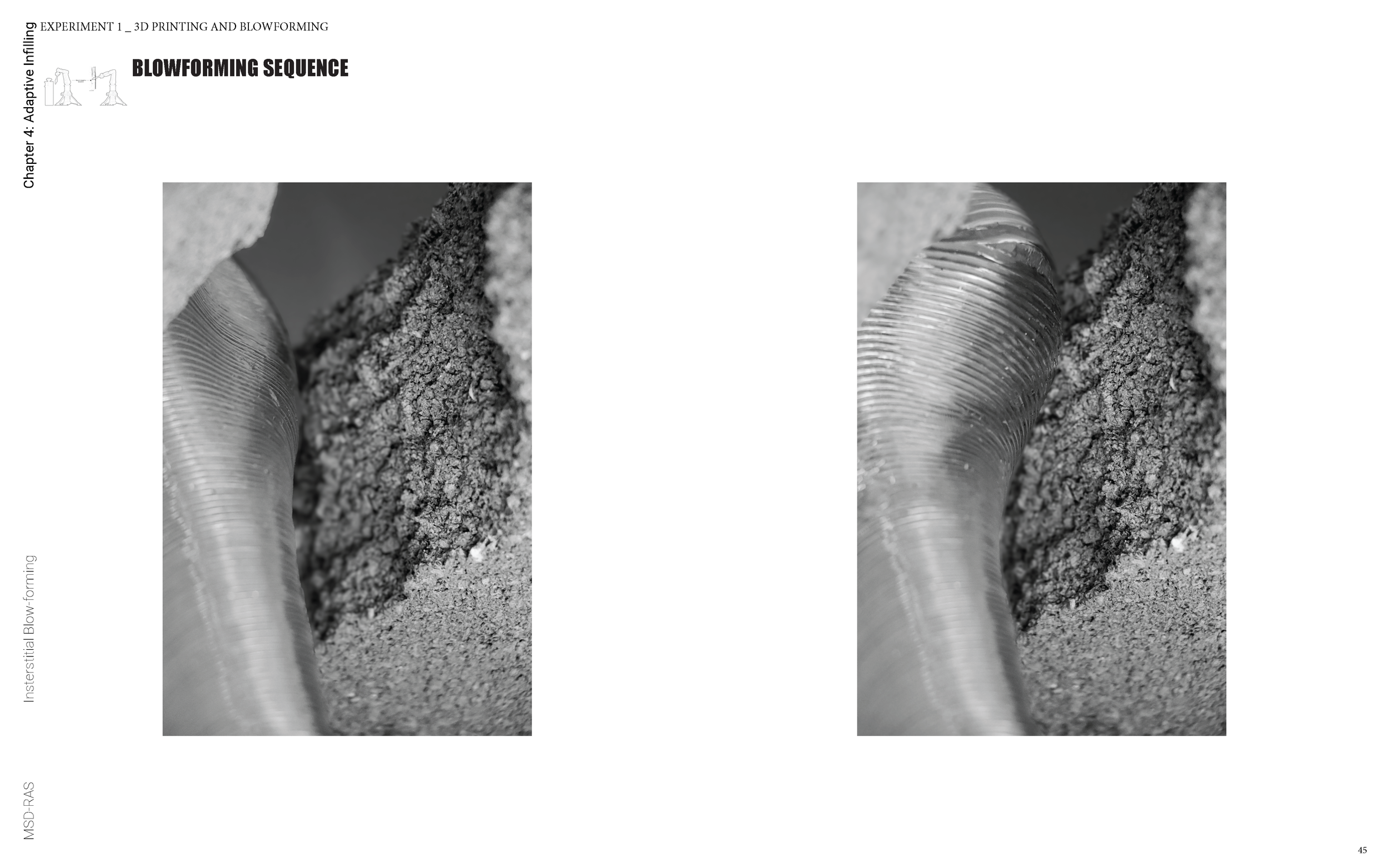

This research develops a real-time, in-situ adaptive robotic blowforming process that fills building cracks and voids. in ruined architectural structures. It simultaneously shapes and insertsusing thermoplastic printed formsmaterials guided byand computer vision with a. A custom 3D point cloud segmentation algorithm. is developed to detect voids, which are then filled by blow-forming 3D printed PETG pre-forms.T By combining thermoplastic blow-forming, real-time crack detection through point cloud segmentation, and robotic automation, the workflow enables site-specific , adaptive revitalizationrestoration that celebrates the uniqueness of ruined buildings. Granular PETG 3D-printed preforms, optimized for interlocking geometries, are dynamically heated and inflated to fill detected voids — fusing preservation, spatial provocation, and augmentation into a unified architectural strategy. This research positions robotic-assisted thermoforming not merely as a fabrication towardsmethod but as a celebration of imperfection, transforming cracks and gaps into both functional and aesthetic opportunities. By embracing rather than concealing damage, the work highlights and honors the historical decay narratives embedded within architectural ruins.

1 Introduction

Architectural ruins embody layers of history, memory, and material decay. Yet, once mortar fails or bricks shift, cracks become entry points for water, microbes, and further deterioration. Conventional conservation often “stitches” ruins invisibly or imposes new skins that mask their patina; both approaches can dilute the material authenticity and narrative resonance of the ruin itself.

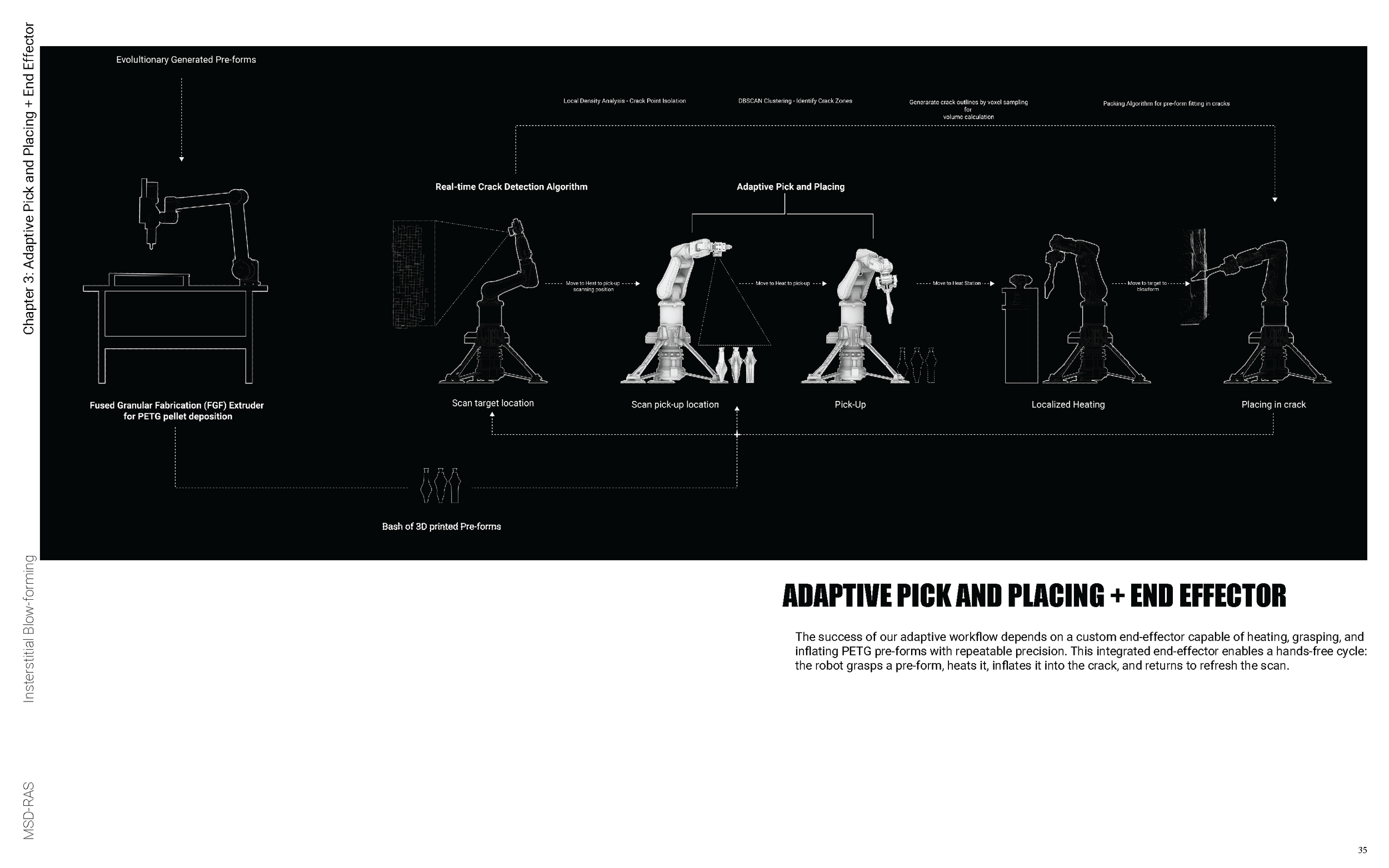

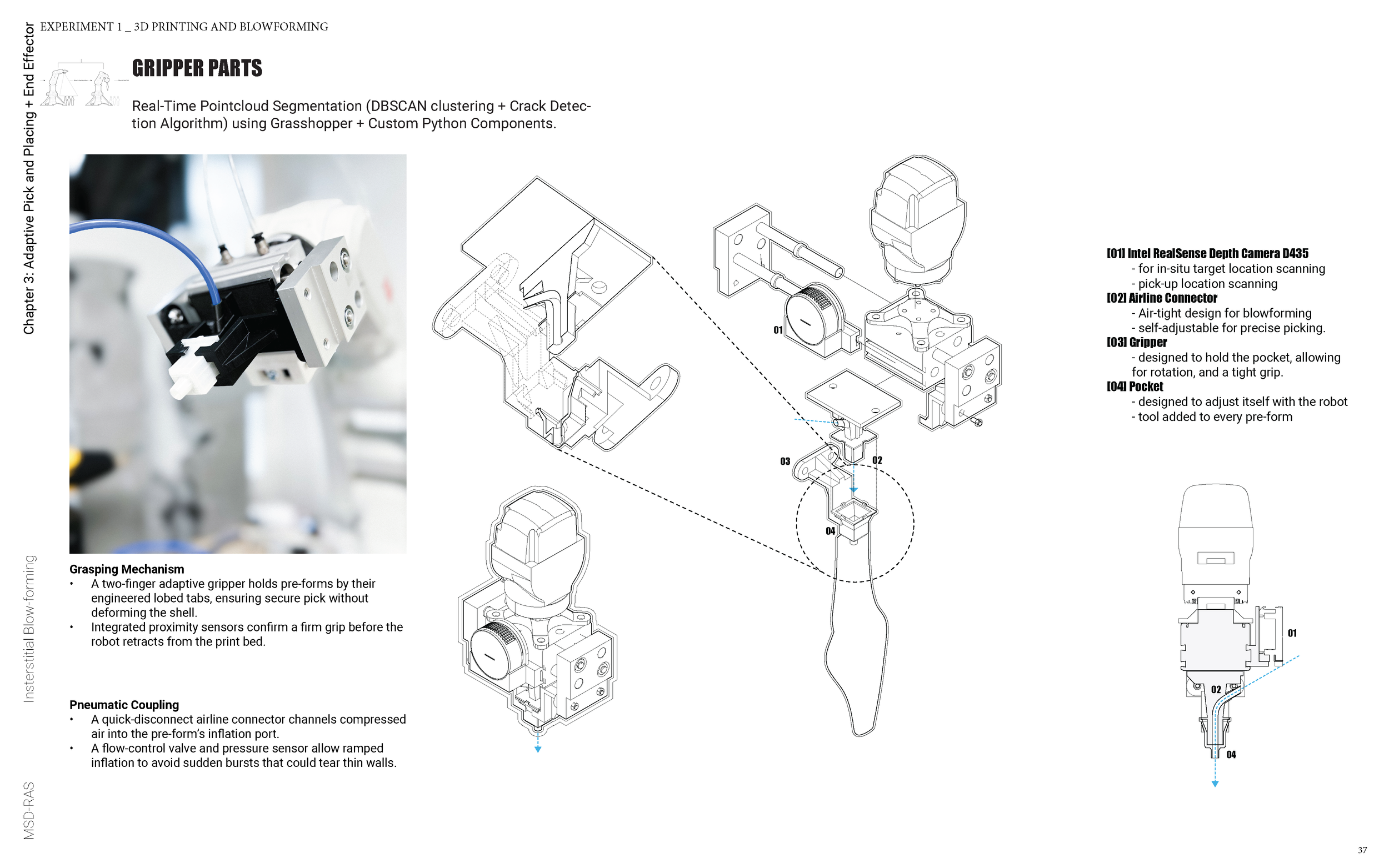

Several architecturally situated artistic explorations—such as Gordon Matta‑Clark’s radical excavations (Matta-Clarck 1975), or Ryan Luke Johns’s dry‑stone robotic assembly (Johns et al. 2023)—have begun to interrogate the space between ruin and renewal. This work aims to contribute to this line of thought, but none offer with a fully automated, site‑responsive method that both stabilizes and celebrates damage. In this context, we ask: Can robotic automation, coupled with real‑time 3D scanning and thermoplastic blow‑forming, adaptively revitalizerepair and augment ruin sites—transforming cracks from liabilities into expressive design elements? Our proposed workflow closes the loop between sensing and fabrication: real‑time point‑cloud segmentation isolates cracks; a generative algorithm produces interlocking PETG pre‑forms; and a robot end‑effector heats and inflates each pre‑form into place. The result: repairs that are legible (the seams remain visible), self-supportingstructural (inflated geometries interlock with substrate), and poetic (each fill echoes the ruin’s unique morphology).

2 State of the Art

Robotic Adaptive Fabrication: Robotic systems have increasingly combined in‑situ sensing with material deposition. Johns et al. demonstrate by dry‑stackinged masonry using LiDAR feedback to autonomously place stone units, highlighting robots’ capacity for site‑specific assembly (Johns et al. 2023). Caltanissetta et al. integrate thermal monitoring into large‑scale additive manufacturing (BAAM), adjusting bead parameters in real time (Caltanissetta et al. 2022). However, these methods producetarget new constructsion, and others focus on machine-powered track detection (Kouzehgar et al. 2029, Ghadimzadeh et al. 2024)—few address repair within existing, fractured assemblies.

Institution: University of Pennsylvania

Lab: Advanced Research and Innovation lab

Instructor: Robert Stuart Smith, Laia Mogas-Soldevila, Jeffrey Anderson, Nathan King

Lab Managers: Nicholas Sideropoulos, Shunta Moriuchi

In Collaboration with: Burcu Gocen

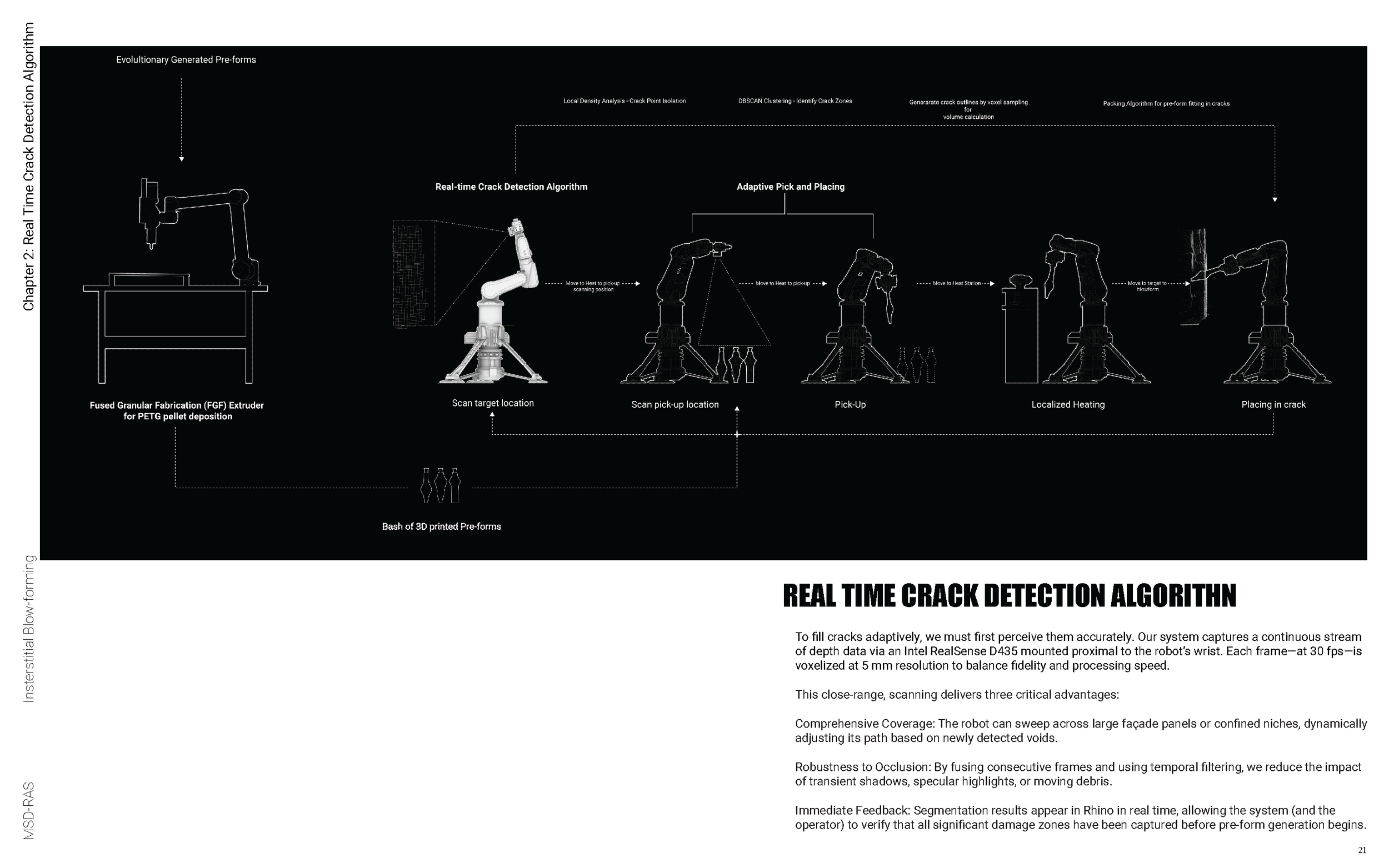

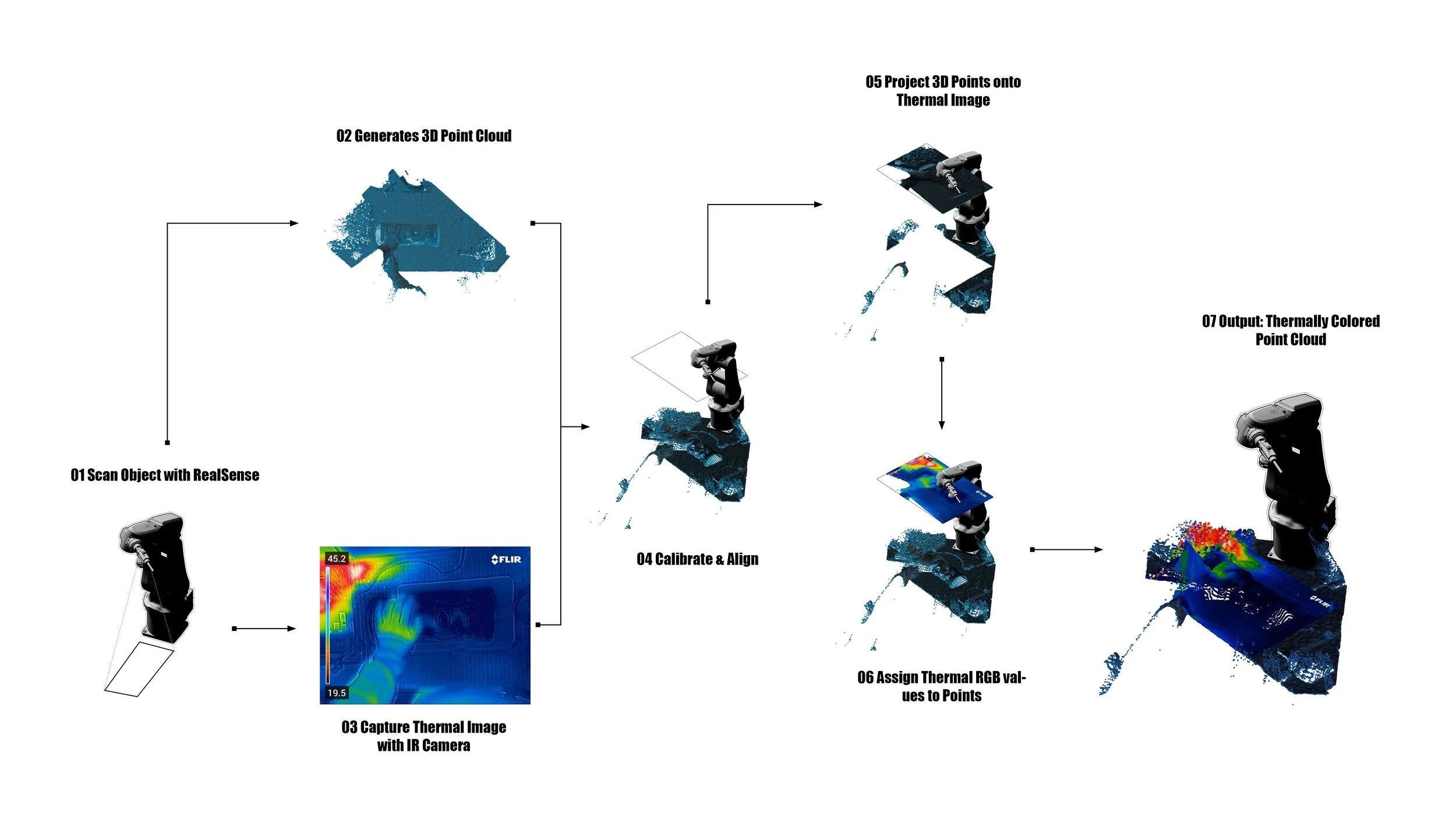

Robot Calibration

In this step, we calibrate the robot with the point cloud segmentation algorithm for adaptive pick and placing execution.

A localized heating diagram: illustrates the simulation workflow in Grasshopper that predicts blow-forming

Thermo-Camera Mapping to Pointcloud Data: This process proposes a feedback driven system for thermoforming.