adaptive pick & placing

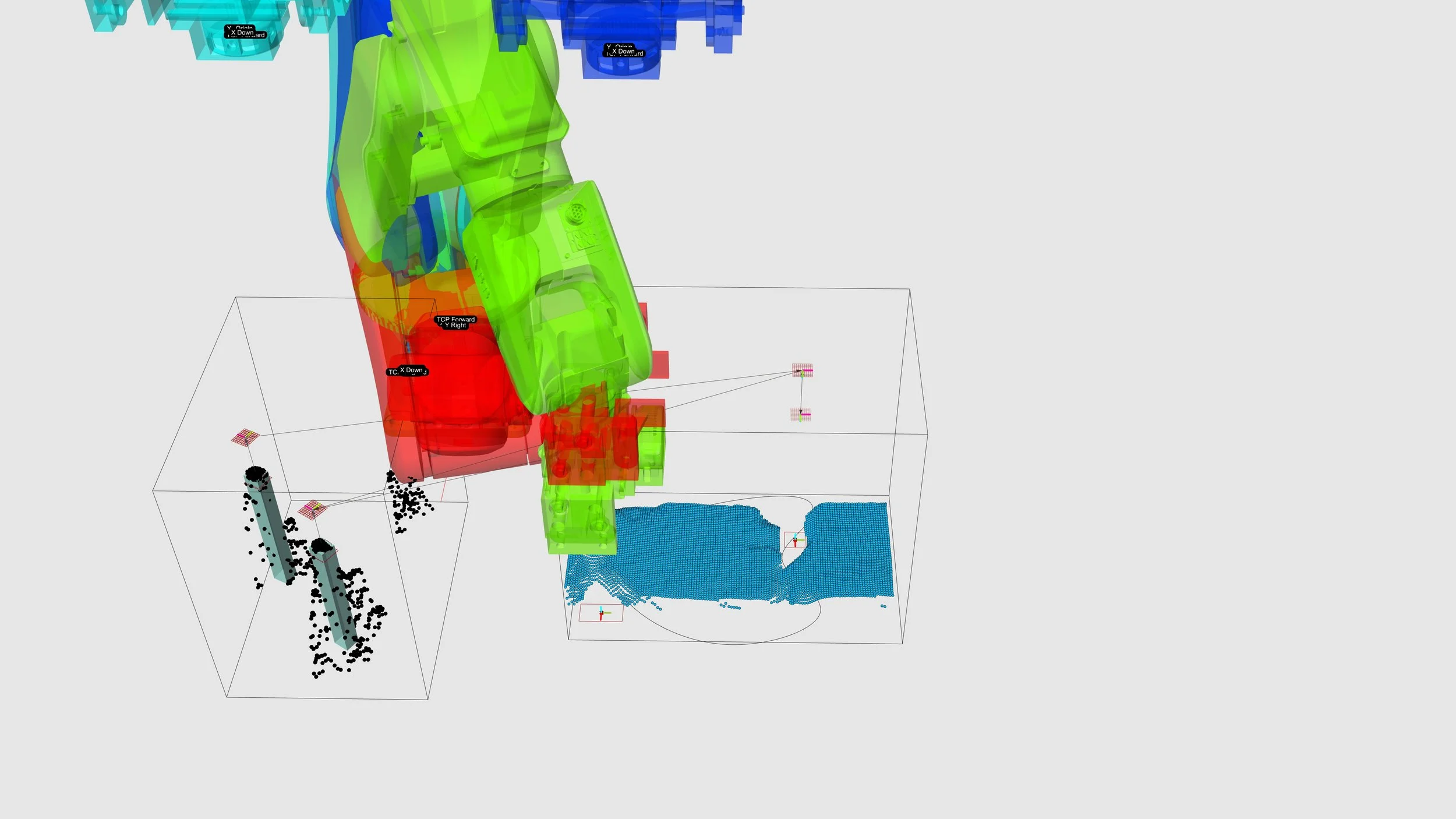

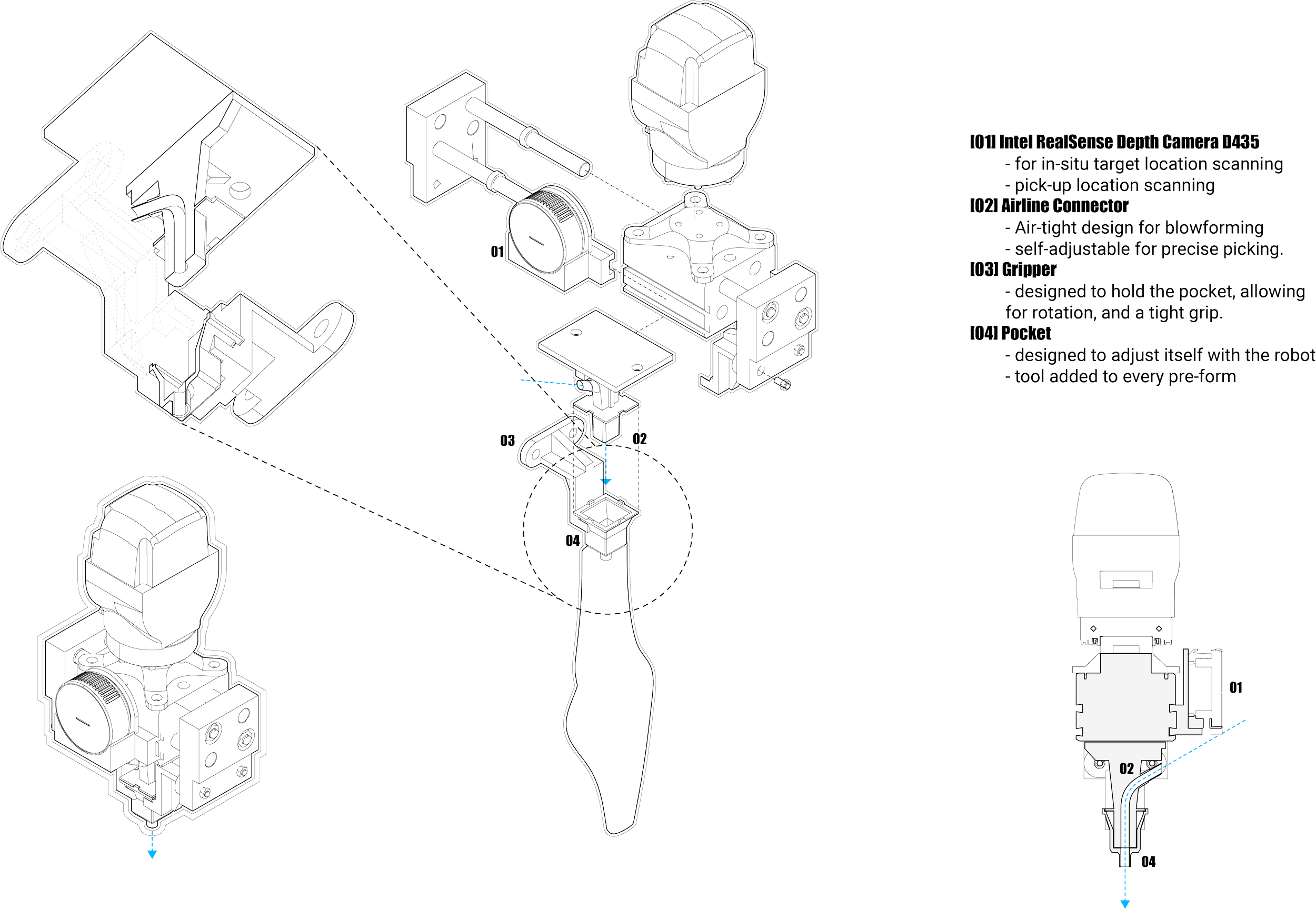

This project developed an adaptive robotic workflow capable of detecting voids in materials and adjusting placement strategies in real time. Using an Intel RealSense depth camera, point-cloud data was down-sampled, clustered with DBSCAN, and analyzed for density to identify potential placement zones.

The workflow included:

Surface Analysis – extracting normals and clustering regions with voids.

Outline Generation – convex hull calculations to define material boundaries.

Robotic Placement – using a pneumatic gripper to position preforms adaptively.

This approach reduces dependency on fixed toolpaths, allowing robots to respond dynamically to unpredictable material conditions.

Lab: Advanced Research and Innovation Lab at the University of Pennsylvania

In Collaboration with: Burcu Gocen